ITO Glass Indium Tin Oxide Glass For Laboratory

Description

Technical Parameters

ITO Glass indium tin oxide glass for laboratory

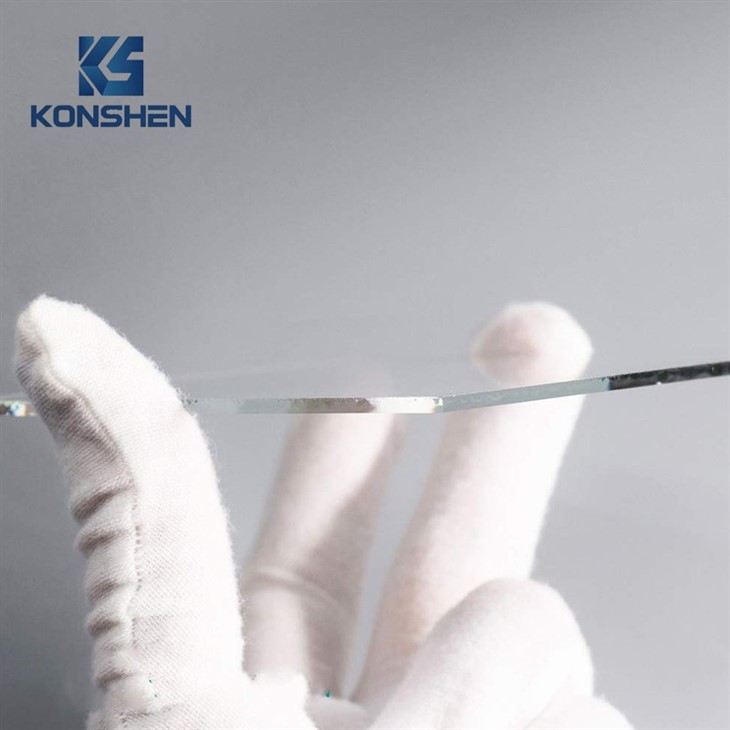

ITO glass, also known as indium tin oxide glass, is a transparent conductive glass that contains a thin layer of indium tin oxide coating. It is commonly used in laboratory settings and various other applications that require transparent electrodes or conductive surfaces.

The main purpose of ITO glass is to provide a transparent conductive coating that allows the passage of light while maintaining electrical conductivity. The indium tin oxide layer is deposited onto a glass substrate using techniques like sputtering or chemical vapor deposition.

ITO Glass specification

|

ITO GLASS LIST |

|||||

|

Thickness |

Sheet resistance |

||||

|

1.1mm |

3ohm/sq~100ohm/sq |

||||

|

3mm |

4~6ohm/sq and 3~5ohm/sq |

||||

|

4mm |

25ohm/sq |

||||

|

0.4/0.5/0.7/0.8/1.0/1.5/1.8/2mm |

7~10ohm/sq |

||||

|

specification |

Sheet resistance |

Conductive film thickness |

Transmittance |

Etching time |

|

|

3 ohm |

3-4ohm |

380±50nm |

≥80% |

≤400S |

|

|

5 ohm |

4-6ohm |

380±50nm |

≥82% |

≤400S |

|

|

6 ohm |

5-7ohm |

220±50nm |

≥84% |

≤400S |

|

|

7 ohm |

6-8ohm |

200±50nm |

≥84% |

≤400S |

|

|

8 ohm |

7-10ohm |

185±50nm |

≥84% |

≤400S |

|

|

15 ohm |

10-15ohm |

135±50nm |

≥86% |

≤400S |

|

|

20 ohm |

15-20ohm |

95±50nm |

≥87% |

≤400S |

|

|

30 ohm |

20-30ohm |

65±50nm |

≥88% |

≤400S |

|

Here are some key features and uses of ITO Glass indium tin oxide glass in laboratory settings:

Transparency: ITO glass is highly transparent, allowing for clear observation and measurement of samples or experiments conducted on it.

Conductivity: The indium tin oxide coating on ITO glass provides excellent electrical conductivity. This feature is particularly useful in applications requiring the conduction of electric current or the use of electrodes.

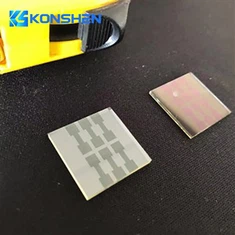

Electrodes and Sensors: ITO glass is commonly used as a substrate for manufacturing electrodes and sensors. It can be patterned or etched to create specific electrode geometries for applications such as electrochemical measurements, biosensing, or microfluidics.

Display and Optoelectronics: ITO glass is extensively used in the fabrication of displays, touchscreens, and optoelectronic devices due to its transparency and electrical conductivity. In a laboratory setting, it may be employed in experiments related to displays, optoelectronics, or as a component of specialized equipment.

Coatings and Surface Modification: ITO glass can be used as a coating material to provide conductivity to non-conductive surfaces. It can also serve as a substrate for surface modification, such as the deposition of thin films or nanomaterials for various experimental purposes.

Solar Cells: ITO glass is utilized as a transparent electrode in solar cell technology, enabling efficient light transmission and electron extraction. In laboratory research on photovoltaics, ITO glass might be employed as a component in experimental setups.

Antistatic Applications: Due to its conductive properties, ITO glass can be used for antistatic purposes in laboratory environments. It helps to dissipate static charges and prevents damage to sensitive equipment or samples.

It is worth noting that while ITO Glass indium tin oxide glass offers excellent electrical conductivity and transparency, it has some limitations. It is relatively brittle and can be susceptible to mechanical damage. Additionally, the cost of indium, one of the main constituents of ITO, can be high.

When using ITO glass in a laboratory, it is important to handle it with care, avoid scratching or damaging the surface, and follow proper cleaning procedures to maintain its performance.

- LCDs

- Touchscreens

- OLEDs

- Solar cells

- Microscopy

- Electrochemical studies

- Biosensors.

Working Environment Overview

FAQ

Q: What does ITO stand for?

A: ITO stands for Indium Tin Oxide.

Q: What is ITO glass used for?

A: ITO glass is used for a variety of applications, including transparent electrodes in LCDs, touchscreens, OLEDs, solar cells, microscopy, electrochemical studies, and biosensors.

Q: How is ITO glass made?

A: ITO glass is made by depositing a thin layer of indium tin oxide onto a glass substrate using techniques like sputtering or chemical vapor deposition.

Q: What are the properties of ITO glass?

A: ITO glass has a combination of transparency and electrical conductivity. It allows light to pass through while enabling the flow of electric current.

Q: Is ITO glass expensive?

A: Indium, one of the main components of ITO, is relatively rare and expensive. Therefore, ITO glass tends to be more costly compared to other transparent conductive materials.

Q: Can ITO glass be patterned or etched?

A: Yes, ITO glass can be patterned or etched using techniques such as photolithography or laser ablation to create specific electrode configurations or designs.

Hot Tags: ito glass indium tin oxide glass for laboratory, China ito glass indium tin oxide glass for laboratory manufacturers, suppliers

Delivery & Payment

Packaging:

Step 1: PE film coating(Normally) / paper(For seashipment prevent wet).

Step 2: Kraft paper for fixation.

Step 3: Carton for glass safety protection.

Step 4: Custom make plywood case with hinge for custom(fumigation + convenient inspection) convenience.

Step 5: Packing strap for further fixation.

Port

Shenzhen or Hongkong

Previous

Ito Coated Glass SubstrateSend Inquiry