Description

Technical Parameters

What Is ITO Conductive Glass?

ITO glass is a type of transparent conductive glass that is coated with a layer of ITO (indium tin oxide) conductive film on its surface. The ITO film offers excellent conductivity and transparency, making it highly desirable for use in various electronic devices such as liquid crystal displays, touch screens, solar cells, and optoelectronic devices.

The principle behind ITO glass is that its conductivity and optical transparency are achieved through the transport of carriers in the indium oxide and tin oxide lattices. ITO thin films have high transparency in the visible light range, as well as good transmittance in the ultraviolet and near-infrared spectral ranges. When an external electric field is applied to the ITO film, the movement of electrons in the film produces conductivity.

ITO Working temperature: up to 300 degrees centigrade

FTO Working temperature: up to 600 degrees centigrade

What is FTO Glass?

FTO (Fluorine-doped Tin Oxide) conductive glass refers to a type of glass that is coated with a thin layer of Fluorine-doped Tin Oxide material. FTO is a transparent conductive material widely used in various optoelectronic applications.

FTO conductive glass is known for its high electrical conductivity and optical transparency. It is commonly used in devices that require both electrical conductivity and transparency, such as solar cells, touch panels, and electrochromic devices.

The fluorine doping in FTO helps enhance its conductivity by increasing the number of free charge carriers. This makes it suitable for applications that require efficient electrical current flow while maintaining good optical properties.

FTO conductive glass is often used as a substrate in thin-film deposition processes. Thin films of semiconductor materials or other functional materials can be deposited on the FTO-coated glass to create devices or components with specific electrical or optical properties.

Overall, FTO conductive glass plays a crucial role in various electronic devices where transparent and conductive surfaces are required simultaneously.

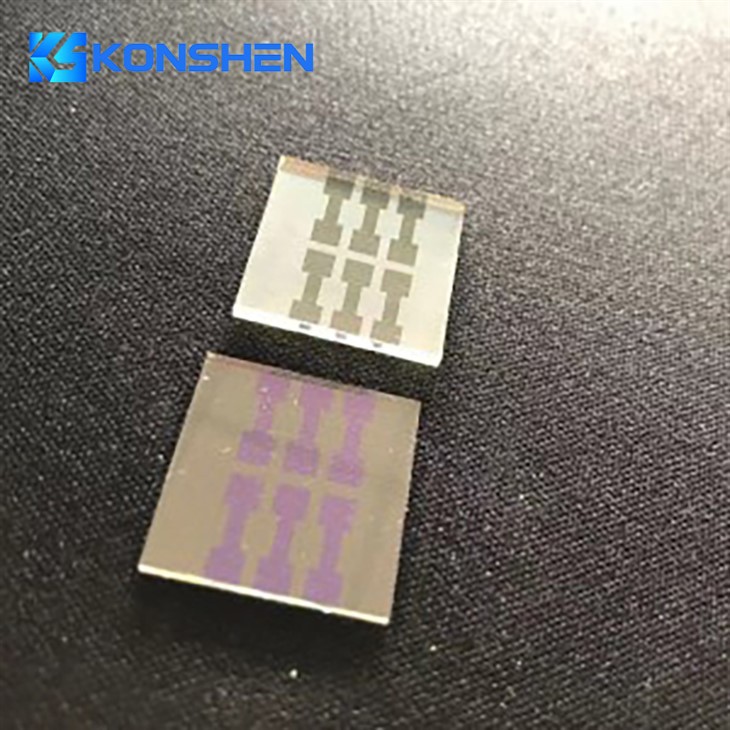

ITO Patterns can be customized by your requirements.

Glass: NSG Soda Lime Glass (SLG)

Glass Transition Temperature: 564°C (1,047°F )

Dimension: 1" x 1" (25.4 mm x 25.4 mm), 2" x 2", 4" x 4", or can be customized.

Special Patterns: can be customized according to customer provided drawings.

Etching Capability: Laser etching, wet etching for detailed patterns. Both techniques have a resolution of +/- 50um.

Sheet resistance: 5-7 ohm/sq, 7-9 ohm/sq, 12-15 ohm/sq, 18 ohm/sq, 30 ohm/sq, 50 ohm/sq,100 ohm/sq, or can be customized.

Glass thickness: 1.1 mm is standard, other thickness can be customized

Transmittance: >80%

Typical RMS < 5 nm

Application

OLED, OPV, electrochromic device

e-book

major university laboratories,

biological experiments,

solar cells,

electrochemical experiment (electrode),

other new technology areas

Edge Treatment

Working Environment Overview

Factory Overview & Customer Visit

Company Profile

Customer Visit

FAQ

Q: Should glass be tempered and what's the difference between Chemical tempered and Physical tempered?

To small size/thickness less than 3.2mm,we recommend chemical tempered.(surface toughen by 6-7H).

To bigger size/thickness above 3.2mm, we recommend physical tempered.

Base on thermal tempered, the fragmentation test standard / partical sizes & quantity could be set base on different thickness.

The glass flatness could be asked after tempering.

Q: What kind of glass will be used?

LightingWe usually use clear / ultra clear float glass for production, depends on customer's need.

Cover glassWe usually use AGC(Dragontail) for production, but also available in gorilla/NEG etc. base on customer's need

Furniture glass We usually use high quality flat/bending glass

Q. Do you accept small order?

Any order quantity is welcome. But some type of products are high cost that not suitable for small order.

Q: Can I get samples and check your Quality?

Yes. Contect our sales with detailed Requirements /Drawings, or just an idea or a sketch. We will deliver the sample to you.

Q: What should I provide to get a quotation?

1. The kind of glass, thickness and size.

2. Drawing of the glass

3. Requirements in details.

4. Order quantity.

5. Others you think is necessary

6. Process balance payment and advise us your opinion on safe delivery.

7. Enjoy your order.

Q: Where is your company? Which port near you? Can I pay a visit?

Welcome. Our factories are located in Guangdong China, near to Shenzhen and Guangzhou port. Please let us know if you want to come, we will advise route guidance in details.

Hot Tags: china ito coating glass with pattern for laboratory, China china ito coating glass with pattern for laboratory manufacturers, suppliers

Delivery & Payment

Packaging:

Step 1: PE film coating(Normally) / paper(For seashipment prevent wet).

Step 2: Kraft paper for fixation.

Step 3: Carton for glass safety protection.

Step 4: Custom make plywood case with hinge for custom(fumigation + convenient inspection) convenience.

Step 5: Packing strap for further fixation.

Port

Shenzhen or Hongkong

Send Inquiry