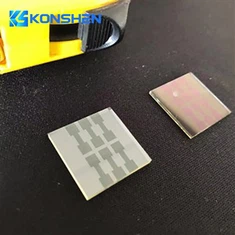

Indium-Tin Oxide Glass

Description

Technical Parameters

What Is ITO Conductive Glass?

Applied to substrates like glass, indium tin oxide is a transparent conducting oxide made of indium, tin, and oxygen. utilizing a magnetron measuring technique to deposit silicon dioxide (SiO2) and indium tin oxide (commonly known as ITO) thin layers on the foundation of soda-lime or borosilicate glass. Due to its electrical conductivity and optical transparency characteristics, ITO is one of the most commonly used transparent conducting oxides.

Working Temperature

Up to 300 degrees centigrade (If work temperature must be up to 600 degree, FTO is also available)

Indium Tin Oxid (ITO) coated glass belongs to the group of TCO (transparent conducting oxide) conductive glasses. ITO glass has the property of low sheet resistance and high transmittance, and it is widely used in the production and research of OLED, OPV, electrochromic device, e-book, electrochemistry, Low-Temperature Solution-Processed Perovskite Solar Cells, etc.

What is FTO Conductive Glass?

Fluorine-doped SnO2 transparent conductive glass (SnO2: F), often known as FTO conductive glass.

SnO2, an oxide semiconductor with a broad band gap and a regular tetrahedral gold red structure, is transparent to visible light and has a band gap between 3.7 and 4.0 eV. The SnO2 film benefits from fluorine doping by having high UV absorption, low resistivity, stable chemical characteristics, and excellent acid and alkali resistance at room temperature in addition to superior light transmission for visible light.

Application

- Touchscreens: including those on smartphones and tablets. The glass's transparent nature and conductive coating enable the transparent display of information and the detection of touch inputs.

- Flat-panel displays: including those on LCD televisions and computer monitors. While the transparency of the glass enables the projection of images, the conductive coating on the glass aids in controlling the flow of electrical current through the display.

- Solar Cells: The glass's transparent nature allows light to pass through while its conductive coating aids in collecting the electrical current produced by the solar cells.

Working Environment Overview

Edge Treatment

Factory Overview & Customer Visit

Company Profile

Customer Visit

FAQ

Q: Should glass be tempered and what's the difference between Chemical tempered and Physical tempered?

To small size/thickness less than 3.2mm,we recommend chemical tempered.(surface toughen by 6-7H).

To bigger size/thickness above 3.2mm, we recommend physical tempered.

Base on thermal tempered, the fragmentation test standard / partical sizes & quantity could be set base on different thickness.

The glass flatness could be asked after tempering.

Q: What kind of glass will be used?

LightingWe usually use clear / ultra clear float glass for production, depends on customer's need.

Cover glassWe usually use AGC(Dragontail) for production, but also available in gorilla/NEG etc. base on customer's need

Furniture glass We usually use high quality flat/bending glass

Q. Do you accept small order?

Any order quantity is welcome. But some type of products are high cost that not suitable for small order.

Q: Can I get samples and check your Quality?

Yes. Contect our sales with detailed Requirements /Drawings, or just an idea or a sketch. We will deliver the sample to you.

Q: What should I provide to get a quotation?

1. The kind of glass, thickness and size.

2. Drawing of the glass

3. Requirements in details.

4. Order quantity.

5. Others you think is necessary

6. Process balance payment and advise us your opinion on safe delivery.

7. Enjoy your order.

Q: Where is your company? Which port near you? Can I pay a visit?

Welcome. Our factories are located in Guangdong China, near to Shenzhen and Guangzhou port. Please let us know if you want to come, we will advise route guidance in details.

Hot Tags: indium-tin oxide glass, China indium-tin oxide glass manufacturers, suppliers

Delivery & Payment

Packaging:

Step 1: PE film coating(Normally) / paper(For seashipment prevent wet).

Step 2: Kraft paper for fixation.

Step 3: Carton for glass safety protection.

Step 4: Custom make plywood case with hinge for custom(fumigation + convenient inspection) convenience.

Step 5: Packing strap for further fixation.

Port

Shenzhen or Hongkong

Previous

Ito Glass SheetSend Inquiry