Customize Ito Coated Glass

Description

Technical Parameters

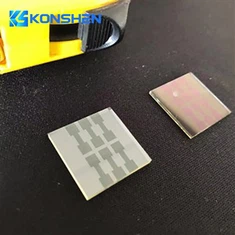

Customize ito coated glass

what is ITO coated Glass

ITO Conductive Glass refers to a type of glass that is coated with a thin film of Indium Tin Oxide (ITO) on its surface. Indium Tin Oxide is a transparent and conductive material that is commonly used in various electronic applications due to its excellent electrical conductivity and optical transparency.

The ITO coating on the glass allows it to have both transparent and conductive properties, making it suitable for applications that require these characteristics. The thin ITO film acts as an electrode, allowing the passage of electrical current while maintaining the transparency of the glass.

ITO Coated specification

|

Property |

Specification |

|

Glass |

NSG Soda Lime Glass (SLG) |

|

Glass Transition Temperature |

564°C (1,047°F) |

|

Dimension |

1" x 1" (25.4 mm x 25.4 mm), 2" x 2", 4" x 4", or Customizable |

|

Special Patterns |

Customizable based on customer-provided drawings |

|

Etching Capability |

Laser etching, wet etching |

|

Etching Resolution |

+/- 50um |

|

Sheet Resistance |

5-7 ohm/sq, 7-9 ohm/sq, 12-15 ohm/sq, 18 ohm/sq, 30 ohm/sq, 50 ohm/sq, 100 ohm/sq, or Customizable |

|

Glass Thickness |

1.1 mm (Standard), Customizable |

|

Transmittance |

>80% |

|

Typical RMS |

< 5 nm |

application

Touch screen

LCD and OLED

solar panel

Electronics and Optics

Electromagnetic Interference (EMI) Shielding

Radiation Control

Smart Home and Wearables

Automobile industry

Optical coating

antistatic coating

thermal controller

biosensor, etc.

working environment overview

FAQ

What are the advantages of ITO Coated Glass?

ITO Conductive Glass offers several advantages, including high transparency, excellent electrical conductivity, durability, and compatibility with various fabrication techniques. It is also customizable and can be tailored to specific design requirements.

What are the typical applications of ITO Coated Glass?

ITO Conductive Glass finds application in various industries, including electronics, optoelectronics, touchscreens, displays, solar cells, automotive, and more. It is commonly used in devices such as smartphones, tablets, LCD and OLED displays, capacitive touchscreens, and photovoltaic panels.

How is ITO Glass manufactured?

ITO Glass is typically manufactured using a vacuum deposition process, where a thin layer of Indium Tin Oxide is deposited onto the glass substrate. The thickness and electrical properties of the ITO coating can be controlled during the deposition process.

Can ITO Conductive Glass be customized?

Yes, ITO Conductive Glass can be customized to meet specific requirements. The thickness of the glass, the sheet resistance, and the dimensions can be tailored to suit the intended application. Additionally, custom patterns or designs can be created on the glass surface.

How do I clean and maintain ITO coating Glass?

ITO coating Glass can be cleaned using non-abrasive, lint-free cloths or sponges. It is important to avoid using harsh chemicals or abrasive materials that may damage the coating. Regular cleaning helps maintain its optical and electrical performance.

What is the sheet resistance of ITO coated Glass?

The sheet resistance of ITO glass requirements of the application. Custom sheet resistance values can also be achieved.

Is ITO Glass compatible with other fabrication processes?

Yes, ITO Conductive Glass is compatible with various fabrication processes, including cutting, shaping, etching, and bonding. It can be incorporated into complex designs and integrated with other materials to meet specific device requirements.

Hot Tags: customize ito coated glass, China customize ito coated glass manufacturers, suppliers

Delivery & Payment

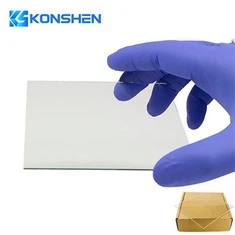

Packaging:

Step 1: PE film coating(Normally) / paper(For seashipment prevent wet).

Step 2: Kraft paper for fixation.

Step 3: Carton for glass safety protection.

Step 4: Custom make plywood case with hinge for custom(fumigation + convenient inspection) convenience.

Step 5: Packing strap for further fixation.

Port

Shenzhen or Hongkong

Send Inquiry