Huizhou Konshen Glass Co., Ltd is a comprehensive deep-processing enterprise integrating glass technology research and development, production and sales, with highly automated production line. Specializing in the production of AR/AG/AF/ITO Coating glass, Solar Glass, Laser Reflective Mirror, Cover Glass For Electronic Devices, Switch Panels, Lighting glass, Borosilicate Glass, Quartz Glass, Tempered glass, Curved glass, laminated glass etc.

Why Choose Us

Various Products

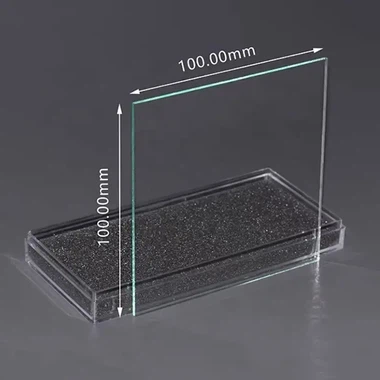

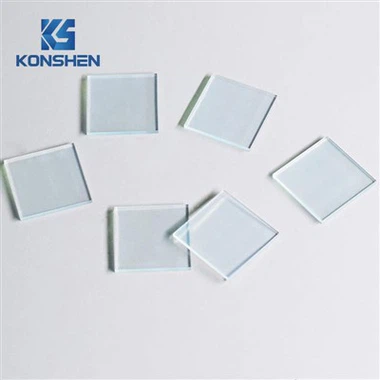

We specialize in the production and processing of a wide variety of glass products, ranging in thickness from 0.23mm to 15mm. Our extensive product line includes, but is not limited to AG (anti-glare) Glass, AR (anti-reflective) Glass, AF (anti-fingerprint)Glass, ITO (indium tin oxide) Glass, Solar Glass Solutions.

Quality Control

In order to present the best performance, we conduct high standard tests of each product between every step.

Professional Team

We provide leading analysis, testing, quality assessment and failure analysis solutions. As recognized experts in the field of glass, we provide our customers with reliable solutions, explanations and advice.

Certification

Our products have passed qualification certifications in multiple countries. Our products are qualified by ISO 9001, RoHs, HF and REACH certifications.

Anti-glare Glass is produced by etching (via acid bath) one or both surfaces of the glass. The etching process is very precise and leaves the glass with an incredibly consistent etched finish across the entire surface. This etched surface disperses light as it hits the surface of the glass, virtually eliminating glare. This allows the end user to see transmitted images and videos very clearly – even in direct sunlight. Anti-glare Glass works best with high resolution displays. Anti-glare is measured in gloss units and is available in numerous gloss (etching) levels. The gloss levels range from 60 to 140. Anti-glare Glass is available in both Low Iron a Soda Lime gloat glass.

Benefits of Anti-Glare Glass

Clarity of Vision Have Both Improved

More light will reach your eye since your lenses will not reflect light. This improves visual acuity and lowers the need to squint, especially while performing tasks that require a lot of concentration, like night driving or working on a computer.

Improved Sporting Ability

In many outdoor activities, glare is a significant issue. Fishing, skiing, snowboarding, and baseball are all activities that take place in bright environments with a lot of glare potential. Anti-Glare Glass can help cut down on this glare and provide you a clearer field of view.

Reduced Strain on the Eyes

During deep concentration tasks or work on a screen, glare can be very distracting. You are straining your eyes if you have to squint to see something. Eliminating glare during these chores will reduce eye strain.

Exposure to Blue Light is Reduced

Phones, laptops, tablets, and televisions all emit hazardous blue light. Anti-glare coatings can help to reduce blue light exposure, enhance sleep patterns, and reduce eye strain. These can be found on a lot of blue light blocking glasses (also called computer glasses).

Application of Anti-Glare Glass

Museum Showcases

In museums, glass displays are used to protect precious artifacts from damage or distress, while presenting them in the best possible light. But sometimes the glass itself can act as an obstruction to the view. Unwanted glare, reflections or reduced lighting levels prevent visitors from having a crystal-clear view and seeing the object in its original color. Using anti-glare glass to reduce unwanted glare and reflection enables closer, more intimate interaction with the displayed object.

Picture Frames

Choosing the right glass for picture frames is essential. Select the right glass and you can reduce glare and reflect light away from the glass, maintaining the integrity of the picture, photograph or painting.

Digital Signage

Choosing the right glass for interior and exterior digital signage applications such as Public Information Displays, Digital Signage, traffic displays, retail signs, embedded devices and biomedical displays is crucial. The right glass can provide displays with optimal aesthetic features combined with performance attributes such as laminated, UV protection, and EMI (Electromagnetic Interference) shielding.

Manufacturing Process of Anti-Glare Glass

Melting and Refining

To make clear glass, need the right set of raw materials is required. This consists of silica sand (SiO2), sodium oxide (Na2O) from soda ash, calcium oxide (CaO) from limestone/dolomite, dolomite (MgO), and feldspar (Al2O3). These ingredients are mixed in the right proportion, and the entire batch is flown into a furnace heated to 1500 degrees Celsius.

Float Bath

The molten material from the furnace flows into the float bath, consisting of a mirror-like surface made from molten tin. This material enters the bath at 1500 degrees Celsius and leaves the bath at around 650 degrees Celsius. Its shape at the exit is like a solid ribbon.

Coating for Anti-Glare Glass

After that, if one is producing anti-glare glass surfaces, then coating procedures are followed in which either a hard coat or a soft coat is applied on the surface of the cooled ribbon at high temperatures.

Annealing

Next, a process called annealing is done to remove the internal stresses built up in the glass. This process allows the glass ribbon to pass through a layer that eliminates any pressures on the glass surface and gradually cools it to give it its final hardened form. This makes it easier to cut the glass and shape it accordingly.

Inspecting

More than 100 million inspections can be made through acute and advanced inspection technology throughout the glass manufacturing procedure to identify air bubbles, stresses, or grains of sand that refuse to melt. This is essential in quality-proofing the final form of glass.

Cutting to Order

Finally, diamond steels are used to trim and cut the glass ribbons into square shapes.

How to Clean Anti-Glare Glass

Gather Your Cleaning Supplies and Rinse the Anti-Glare Glass

You'll want to set up the cleaning location at a sink that has access to lukewarm water. Use some dish soap or a glass cleaning solution, two of the best eyeglass cleaners for anti-glare glass. Avoid anything that has harsh chemicals. You'll also need a clean microfiber cloth. Be sure to cleanse your hands before you get started. Then, you'll want to rinse the anti-glare glass under warm water.

Add a Tiny Bit of Your Cleaning Solution to the Anti-Glare Glass

Whether you use dish soap or anti-glare glass cleaner, now's the time to put some on the anti-glare glass. Add no more than a pea-sized amount of cleaner to each anti-glare glass.

Massage the Cleaner into the Anti-Glare Glass

Using your hands, work the soap or anti-glare glass cleaner into the glass, first get rid of any signs of debris.

Run the Lukewarm Water over Your Anti-Glare Glass

To get rid of the soap, pass your anti-glare glass under the lukewarm water. Look over your anti-glare glass to verify you've gotten the cleaner off. Otherwise, your anti-glare glass may smudge.

Dry Your Anti-Glare Glass with a Microfiber Cloth

Start by giving your anti-glare glass a quick shake over the sink to make sure there's no water left. Then, dry them carefully with your microfiber cloth. Your local optical store can give you one of the best anti-glare glass cleaning cloths when you come in to purchase anti-glare glass.

Employing an intricate process, the anti fingerprint coating method involves applying a thin, transparent layer onto glass within a controlled environment, thwarting the persistence of fingerprint marks and enhancing the material's overall performance. Anti-fingerprint glass is that they prevent your tablet screen from getting covered with oily and greasy fingerprints, which can make your tablet look dirty and unappealing, and interfere with your touch sensitivity and accuracy. Anti-fingerprint glass is usually smooth and glossy, and have a slick feel that allows your fingers to glide easily.

Benefits of Anti-Fingerprint Glass

Effortless Cleaning

With anti-fingerprint glass's innovative surface technology, faint fingerprints and smudges are easily wiped away, saving time and frustration. Its properties make cleaning effortless, freeing you from the hassle of constantly buffing out marks.

Versatility in Design

One notable benefit of anti-fingerprint glass for kitchen cabinets is its versatility in design. This innovative material offers a wide range of design and aesthetic possibilities, allowing you to explore various styles and themes to suit your preferences.

Sleek Aesthetics

This innovative glass maintains a flawless appearance by repelling unsightly fingerprints and smudges, ensuring cabinets retain their pristine allure. With a smooth, clean surface that resists marks and stains, the glass exudes a polished, modern ambience, elevating the overall aesthetic appeal.

Durability

Durability stand out as key benefits of anti-fingerprint glass. It offers exceptional resistance to wear and tear, ensuring longevity and maintaining a sleek appearance even in high-traffic areas. This makes it ideal for withstanding daily use, accidental impacts, and moisture exposure.

Fingerprint Resistance

Like its name, anti-fingerprint glass resists fingerprints and smudges on its surface. The glass's specialized coating ensures it remains sleek and smudge-free despite the frequent handling of kitchen cabinets.

Water Repellant

Anti-fingerprint glass is also stained, mark, smudge-resistant, and water-repellant. This feature ensures that spills, splashes, and moisture bead off the surface, preventing water damage and maintaining the pristine appearance of the cabinets for longer periods.

Function of Anti-Fingerprint Glass

Enhanced Scratch Resistance

Most anti-fingerprint glass are made of advanced technology that makes the surface scratch-resistant. The coating penetrates deep into the surface, providing a hard protective layer that can withstand abrasions and scratches. The glass effectively reduces the wear and tear of the device's surface, thereby increasing its durability. The enhanced scratch resistance of the anti-fingerprint glass ensures your device looks and feels new, even after prolonged use.

Improved Touch Sensitivity

The primary aim of anti-fingerprint glass is to keep the surface free of smudges and marks. The anti-fingerprint coating removes oil and grime residue, creating a smooth and responsive surface. Increasing touch sensitivity ensures that users have a seamless experience while using their devices, enhancing productivity and making the process more efficient.

Enhanced Clarity

One of the most significant benefits of anti-fingerprint glass is that it enhances the screen's clarity. The anti-fingerprint coating on the glass removes any oily residue, dust, or smudges on the surface and restores the surface's natural glossy look. The improved clarity enhances the visual experience by providing sharp images with vivid colors and improved contrast.

Applications of Anti-Fingerprint Glass

Appliances

Kitchen appliances, such as refrigerators, ovens, and dishwashers, are often coated with anti-fingerprint glass to maintain their pristine appearance and ease of cleaning.

Countertops and Backsplashes

In the kitchen, anti-fingerprint glass is a boon for countertops and backsplashes.

Retail Displays

Retail stores often use anti-fingerprint glass on display screens and product showcases to maintain a professional and inviting shopping environment.

Healthcare Settings

In healthcare, where cleanliness is paramount, anti-fingerprint glass is used on surfaces like medical equipment and touchscreens to reduce the risk of contamination.

Office Buildings

From conference room tables to office desks and reception areas, anti-fingerprint glass elevates the appearance of office spaces and minimizes the need for constant cleaning.

How To Maintain Anti-Fingerprint Glass

Clean Anti-Fingerprint Glass Safely and Effectively

When looking for the right glass cleaners, look for products labeled with terms such as "glass-safe" or "made for glass" to ensure they won't cause any unintended damage. To make your own glass cleaner at home, you will need the following:

1/2 cup white vinegar

1/2 cup rubbing alcohol

2 tbsp corn starch

4 cups warm water

Using safe, non-abrasive ingredients, such as vinegar and rubbing alcohol, along with a microfiber cloth ensures your anti-fingerprint glass will be safe from scratches caused by cleaning.

Watch Children and Pets

Children can scratch glass with their toys, and pets can scratch anti-fingerprint glass with their claws. It's important to watch children and pets around anti-fingerprint glass such as table tops, and windows, and to limit their access to the anti-fingerprint glass, if possible. For example, a baby-gate can keep small children away from rooms with floor-length mirrors.

Remove Minor Scratches from Anti-Fingerprint Glass

No matter how diligent you are in protecting your anti-fingerprint glass, scratches can still happen—but that doesn't mean there's nothing you can do about it. By addressing minor scratches as soon as possible, you can keep the scratches from getting worse and prevent new ones from forming. There are several products that can be used as an easy DIY temporary fix for minor scratches. To fix scratches long-term, it's important to contact a professional.

- Clear nail polish

Clear nail polish can cover and disguise scratches by filling in the scratched area. Clean the area around the scratch with a glass cleaner, and then use the nail polish applicator to carefully apply a thin layer of polish to the scratch. Allow the polish to dry, then use a cloth to remove any excess polish.

- Toothpaste

Toothpaste isn't just good for polishing your teeth—it can also help polish glass. Dab a small amount of toothpaste onto the scratch and gently use a damp cloth to rub it across the surface. Make sure to rub the toothpaste softly to avoid causing more scratches. Wash away the rest of the toothpaste and clean the glass for a finishing touch.

- Baking soda

Creating a paste of baking soda and water can be an effective way to remove scratches from glass. In a small bowl, mix one ½ cup of baking soda with a few tablespoons of water. Once you've made a paste, use a cloth to rub it around the scratched area. Then, clean the glass and assess if the scratch is still noticeable. This method may take a few repeated attempts for the scratch to be completely removed or become less visible.

4-Step Ordering Process

Submit A Quote Request

The process for custom borosilicate glass development begins with a quote request. You can submit a quote request telling us what you're looking to have produced and we can then provide you with a quote on how much your custom product order would cost.

Send Over Your Design

If the quote looks good to you, the next step will be sending us the custom design. Ideally, your design will be in an Adobe Illustrator (.ai) or encapsulated postscript (.eps) format, but we can help you convert the file for free if it isn't. If you don't have a design created, we can help you create a design at no cost!

Review the Proof

Once we have your custom design, we'll then create a proof for you to review so that you can see what your design will look like on your new custom borosilicate glass.

Production & Delivery

Once your invoice is paid, we'll begin production. We'll deliver your custom borosilicate glass straight to you after production.

Our Factory

Our factory is located in Shengkang Industrial Park, Huiyang District, Huizhou City, China. Covering an area of more than 50,000 square meters and currently employs about 150 peoples.

Ultimate FAQ Guide to Solar Panel Glass

Q: What does coated glass do?

Q: Where is coated glass used?

Q: What is coated glass made of?

Q: What is the difference between coated and uncoated glass?

Q: How do you clean a coated glass?

Q: What are the sizes & thicknesses of anti-reflective glass?

Q: What is coated glass?

Q: What are Characteristics of Coated Glass?

UV Protection: Coated glass can be designed to provide effective UV protection, safeguarding interior spaces and occupants from the harmful effects of ultraviolet radiation. This feature is particularly beneficial for spaces with valuable artwork, furnishings, or sensitive materials.

Q: How do you clean coated glass?

Q: How does anti fingerprint glass work?

We're professional coated glass manufacturers and suppliers in China, specialized in providing high quality customized service. We warmly welcome you to buy or wholesale high-grade coated glass at competitive price from our factory. Contact us for more details.

Quartz Coverslip, soda lime borosilicate glass, Anti Fingerprint Tempered Glass