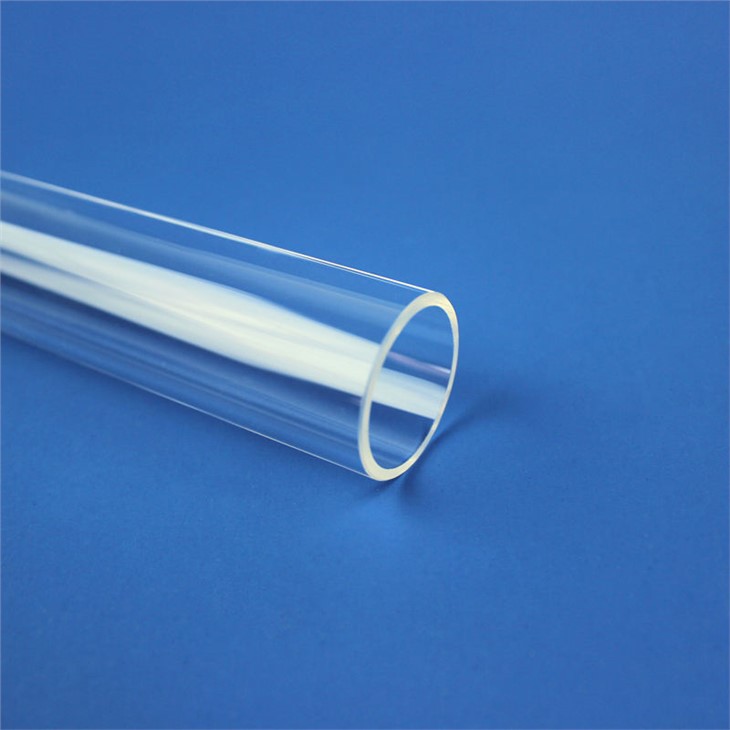

High Borosilicate Glass

Description

Technical Parameters

What is Borosilicate glass?

High borosilicate glass is a type of glass that is made by adding boron oxide to silica glass. It is known for its excellent thermal shock resistance, high chemical durability, and low thermal expansion coefficient, which makes it a popular choice for a wide range of applications.

Borosilicate glass is made by melting a mixture of silica and boron oxide at high temperatures. The addition of boron oxide to the glass composition reduces the thermal expansion coefficient of the glass, making it more resistant to thermal shock. Borosilicate glass also has a high chemical resistance, making it ideal for use in laboratory glassware and chemical processing applications.

What is Borosilicate Glass used for?

High borosilicate glass has several advantages over other types of glass. For example, it can withstand rapid temperature changes without cracking or breaking, making it ideal for use in cooking and baking applications, such as glass baking dishes, as well as in scientific and laboratory applications, such as test tubes and beakers. Additionally, it has a high level of clarity and transparency, making it an excellent choice for use in optics, such as lenses and prisms.

Other applications for high borosilicate glass include solar energy systems, pharmaceutical packaging, and electronic display screens. Its unique properties, including its high strength, chemical resistance, and thermal stability, make it a versatile and valuable material for many different industries.

Overall, high borosilicate glass is a valuable material with a wide range of applications. Its unique properties make it an excellent choice for use in a variety of high-performance applications where strength, durability, and resistance to thermal shock and chemical corrosion are critical.

Technical Parameters

|

Density |

2.30g/cm² |

|

Mohs Hardness |

6.0Mohs’ |

|

Elasticity Modulus |

67KNmm – 2 |

|

Tensile Strength |

40 – 120Nmm – 2 |

|

Poisson Ratio |

0.18 |

|

Coefficient of Thermal Expansion(20-400°C) |

(3.3)*10`-6 |

|

Specific Heat Conductivity(90°C) |

1.2W*(M*K`-1) |

|

Refractive Index |

1.6375 |

|

Specific Heat (J/KG) |

830 |

|

Melting Point |

1320°C |

|

Softening Point |

815°C |

|

Continuous Operating Temperature/Service Life |

150°C |

|

≥120000h(-60°C-150°C) |

200°C |

|

≥90000h(-60°C-200°C) |

280°C |

|

≥620000h(-60°C-280°C) |

370°C |

|

≥30000h |

520°C |

|

≥130000h |

|

|

Thermal Shock |

≤350°C |

|

Impact Strength |

≥7J |

|

Main Chemical Composition % Content |

|

|

SiO2 |

80.40% |

|

Fe203 |

0.02% |

|

Ti02 |

1.00% |

|

B203 |

12.50% |

|

Na20+K20 |

4.20% |

|

FE |

0.02% |

|

Water Tolerance |

HGB 1 |

Edge Treatment

Factory Overview & Customer Visit

Company Profile

Customer Visit

FAQ

Q: Should glass be tempered and what's the difference between Chemical tempered and Physical tempered?

To small size/thickness less than 3.2mm,we recommend chemical tempered.(surface toughen by 6-7H).

To bigger size/thickness above 3.2mm, we recommend physical tempered.

Base on thermal tempered, the fragmentation test standard / partical sizes & quantity could be set base on different thickness.

The glass flatness could be asked after tempering.

Q: What kind of glass will be used?

LightingWe usually use clear / ultra clear float glass for production, depends on customer's need.

Cover glassWe usually use AGC(Dragontail) for production, but also available in gorilla/NEG etc. base on customer's need

Furniture glass We usually use high quality flat/bending glass

Q. Do you accept small order?

Any order quantity is welcome. But some type of products are high cost that not suitable for small order.

Q: Can I get samples and check your Quality?

Yes. Contect our sales with detailed Requirements /Drawings, or just an idea or a sketch. We will deliver the sample to you.

Q: What should I provide to get a quotation?

1. The kind of glass, thickness and size.

2. Drawing of the glass

3. Requirements in details.

4. Order quantity.

5. Others you think is necessary

6. Process balance payment and advise us your opinion on safe delivery.

7. Enjoy your order.

Q: Where is your company? Which port near you? Can I pay a visit?

Welcome. Our factories are located in Guangdong China, near to Shenzhen and Guangzhou port. Please let us know if you want to come, we will advise route guidance in details.

Hot Tags: high borosilicate glass, China high borosilicate glass manufacturers, suppliers

Delivery & Payment

Packaging:

Step 1: PE film coating(Normally) / paper(For seashipment prevent wet).

Step 2: Kraft paper for fixation.

Step 3: Carton for glass safety protection.

Step 4: Custom make plywood case with hinge for custom(fumigation + convenient inspection) convenience.

Step 5: Packing strap for further fixation.

Port

Shenzhen or Hongkong

Previous

No InformationSend Inquiry